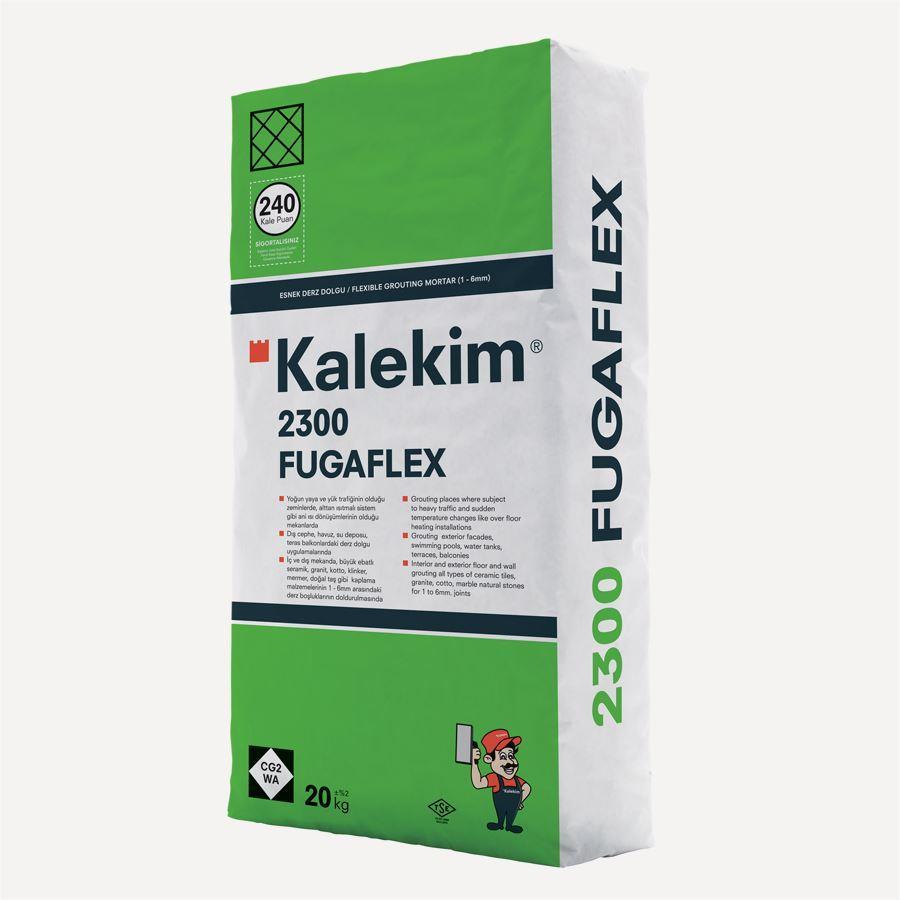

Kalekim Fugaflex White 20 Kg

-41 %

Kalekim Fugaflex White 20 Kg

53.93€

91.69€

Price in reward points: 76000

- Stock: In Stock

- Reward Points: 7600

- Model: CLZ202-1549576

- Weight: 1.00kg

Product Features

It is a cement based, high performance, flexible joint filling material suitable for 1-6 mm joint spacing.

Application Areas

- It is used for filling the joint gaps between 1-6 mm of coating materials such as large sized ceramic, granite, cotto, clinker, glass mosaic, marble, natural stone indoors and outdoors.

- It is used in horizontal and vertical applications in wet areas such as pools and water tanks.

- It gives excellent results in places where there is intense pedestrian and load traffic and sudden temperature changes such as exterior facades, terraces, underfloor heating systems, warehouses.

Features

- Suitable for use in drinking water tanks.

- High flexibility.

- Resistant to freezing - thawing cycle.

- Low water absorbency.

- Provides a smooth surface.

- Does not crack.

- Cures fast and allows the place to be used quickly.

- Resistant to abrasion.

- UV and atmosphere resistant, non-fading, 32 different color options.

Application Instructions

- The adhesive must be cured before joint filling application.

- Joint gaps must be completely cleaned of residues that will prevent adhesion. The depth between the joints should be at least 2/3 of the ceramic thickness.

- For easier cleaning, SERA CARE Surface Protector can be applied to the upper surface of porous and absorbent coating materials such as cotto, clinker, glossy granite ceramic, taking care not to contaminate the joint gaps.

- When highly absorbent coating materials are used, when applying in hot and windy weather, the joints should be moistened with clean water.

- The prepared mortar should be rested for 5-10 minutes to mature. Before starting the application, it should be mixed again for 1-2 minutes.

- The mortar should be spread on the surface and filled into the joint gaps with a rubber trowel with cross movements and the excess should be removed from the surface by scraping.

- When the material filled into the joint gap loses its water and becomes dull, usually after 10-20 minutes, the surface should be cleaned with the help of a damp sponge with circular movements. This period may be shortened in applications made in unsuitable ambient conditions such as direct sun, wind, between coating materials that have been waiting in the sun or with high absorbency. When wiping is done prematurely or with a very watery sponge, color fluctuation problems may be encountered. The sponge should be cleaned at frequent intervals.

- After making sure that FUGAFLEX is dry enough not to drain from the joint, the residues remaining on the surface should be cleaned with a dry cloth.

- If there are mortar residues on the surface caused by improper cleaning, cleaning can be done with SERACARE Cement Remover by following the application instructions 10 days after grouting application.

- Expired or crusted mortar in the container should be discarded.

- Hands and application tools should be washed with plenty of water after application.

- When FUGAFLEX is applied in very hot, dry and windy conditions, it is recommended to sprinkle water on it a few hours after the application to improve the final performance.

It is a cement based, high performance, flexible joint filling material suitable for 1-6 mm joint spacing.

Application Areas

- It is used for filling the joint gaps between 1-6 mm of coating materials such as large sized ceramic, granite, cotto, clinker, glass mosaic, marble, natural stone indoors and outdoors.

- It is used in horizontal and vertical applications in wet areas such as pools and water tanks.

- It gives excellent results in places where there is intense pedestrian and load traffic and sudden temperature changes such as exterior facades, terraces, underfloor heating systems, warehouses.

Features

- Suitable for use in drinking water tanks.

- High flexibility.

- Resistant to freezing - thawing cycle.

- Low water absorbency.

- Provides a smooth surface.

- Does not crack.

- Cures fast and allows the place to be used quickly.

- Resistant to abrasion.

- UV and atmosphere resistant, non-fading, 32 different color options.

Application Instructions

- The adhesive must be cured before joint filling application.

- Joint gaps must be completely cleaned of residues that will prevent adhesion. The depth between the joints should be at least 2/3 of the ceramic thickness.

- For easier cleaning, SERA CARE Surface Protector can be applied to the upper surface of porous and absorbent coating materials such as cotto, clinker, glossy granite ceramic, taking care not to contaminate the joint gaps.

- When highly absorbent coating materials are used, when applying in hot and windy weather, the joints should be moistened with clean water.

- The prepared mortar should be rested for 5-10 minutes to mature. Before starting the application, it should be mixed again for 1-2 minutes.

- The mortar should be spread on the surface and filled into the joint gaps with a rubber trowel with cross movements and the excess should be removed from the surface by scraping.

- When the material filled into the joint gap loses its water and becomes dull, usually after 10-20 minutes, the surface should be cleaned with the help of a damp sponge with circular movements. This period may be shortened in applications made in unsuitable ambient conditions such as direct sun, wind, between coating materials that have been waiting in the sun or with high absorbency. When wiping is done prematurely or with a very watery sponge, color fluctuation problems may be encountered. The sponge should be cleaned at frequent intervals.

- After making sure that FUGAFLEX is dry enough not to drain from the joint, the residues remaining on the surface should be cleaned with a dry cloth.

- If there are mortar residues on the surface caused by improper cleaning, cleaning can be done with SERACARE Cement Remover by following the application instructions 10 days after grouting application.

- Expired or crusted mortar in the container should be discarded.

- Hands and application tools should be washed with plenty of water after application.

- When FUGAFLEX is applied in very hot, dry and windy conditions, it is recommended to sprinkle water on it a few hours after the application to improve the final performance.

Tags:

colezium